igus Chainflex Range, High Flex Cables for Energy Chains

The tricks and ingenious features of the Chainflex® design and why we feel so confident about this design

From the customer’s point of view, a flexible energy supply system only needs to function properly. However, this demand presupposes the perfect operation of all components, including the cables being used in this system. And this is exactly where problems came up in the early 1980s. Due to constantly – and frequently even tremendously – increasing loads resulting from the application of automation technology, guided cables often failed although the energy supply system itself was functioning perfectly. In extreme cases, failures caused by “corkscrews” and core ruptures brought the entire production process to a standstill and resulted in high costs. In order to find a solution to this unsatisfactory situation for its customers, igus® decided to take the initiative. As the first company worldwide, igus® began to develop complete Energy Chain Systems®. Chainflex® cables and Energy Chains® are now being offered as a delivery from a single source and with a system guarantee depending on the application in each case. Based on the increasing know-how gained since 1989 and on the very sophisticated series of tests that have been conducted since then, design principles were and are still being created that help prevent machine downtimes in factories throughout the world today.

How can “corkscrews” be prevented?

Properties of stranding in layers

Stranding in layers is significantly easier to produce and is therefore offered on the market in so-called “chain-suitable” cables at low cost. But what appears to be tempting at first glance can quickly turn into an expensive mistake when a “corkscrew” immobilizes the system being operated with these cables. In the case of stranding in layers, the cable cores are mostly stranded more or less firmly and relatively long in several layers around a center and are then provided with a jacket extruded to the form of a tube. In the case of shielded cables, the cores are wrapped up with fleece or foils. But what, for example, happens to a similarly structured 12-core cable during normal operation? The bending process compresses in the movement of the core, the inner radius of the cable stretches the core in the outer radius. Initially, this works quite well because the elasticity of the material is still sufficient. But very soon, material fatigue causes permanent deformations and then due to excursion from the specified paths, the cores make their “own compressing and stretching zones”: The corkscrew is created, then followed rather quickly by core ruptures most of the time.

Stranding in bundles tried and tested expensively and efficiently millions of times since 1989

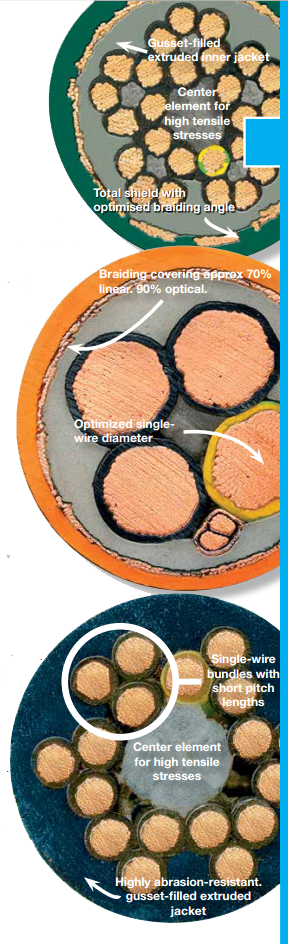

Stranding in bundles eliminates these problems by means of its very sophisticated, multiple stranded internal structure. Here, the litz wires are stranded with a special pitch length first and then the resulting cores are stranded into single core bundles. For large cross sections, this is done around a strain relief element. The next step is the renewed stranding of this core bundle around a tension-proof center – a genuine center cord. Due to this multiple stranding of the cores, all cores change the inner radius and the outer radius of the bent cable several times at identical spacing distances. Pulling and compressing forces balance one another around the hightensile center cord that gives the stranded structure its necessary inner stability. Accordingly, the stranding remains stable even under maximum bending stress.

What are EMC problems and shield wire breakage?

In principle, cable shields must fulfil two tasks:

- Protecting the cables from external interferences

- Shielding any interferences before transmitting them to the outside

In the case of so-called “chain-suitable” cables, for example, the stranding bond of an intermediate layer is wrapped up with foils or fleeces. This stranding bond is supposed to guarantee the separation between the cores and the shield braid. But something that functions quite well for the fixed installation of cables is often quite insufficient in the case of moving cables. This has to do with the fact that the foils and fleeces do not create a bond between the stranding, shield and jacket and may fall apart under stress. Consequently, the metallic shield then rubs on the insulation of the cores – short circuits are then to be expected. Open shields only possess a limited shielding effect in their moved state – motion and expansion reduce this effect even further. The type of shield is therefore an important point that is not even mentioned in some catalogues.

Up to approx, 70% linearly and approx, 90% optically covered cables, igus® eliminates these weak points by means of an optimized internal structure. In virtually all shielded Chainflex® cables, a gusset-filled extruded inner jacket over the stranded structure is therefore used.

This “second jacket” fulfills two tasks:

- It holds the stranded structure together and guides the individual cores in a channel.

- It serves as a firm, round base for a very tight-fitting shield.

Shield wire breakage – and how this can be prevented

During the production of the shield, there are many things that can be done correctly – or incorrectly. Here, an important parameter is the braiding angle. In the case of “chain-suitable” cables, a tensile load of the shield wires in the outer radius of the cable must usually be taken into account. If an unfavorable braiding angle is to be added, the tensile load increases even further and shield wire breakage is the result. The consequences range from reduced shielding effects right up to short circuits whenever the sharp wire ends penetrate through the fleeces or foils into the cores. Here, is a useful tip: If, after the insulation has been stripped off, the shield can be easily pushed back over the jacket, the shield is then usually unsuitable for use in moved flexible energy supply systems! This is a problem that igus® has now solved with its direct approach:

The shield braiding angle determined in long-term tests efficiently neutralizes the tensile forces and is therefore highly suitable for:

- Energy Chains®

- Due to the stable inner jacket, the shield cannot wander uncontrolled.

- The shield itself has a torsion protection effect on the stranded structure.

Jacket abrasion/ jacket breakage

Whereas defects in the internal structure are hardly detectable on the outside, jacket problems strike the eye immediately. The jacket is the first protection for the complicated internal structure. This is why broken, worn and swollen jackets are a serious quality defect. To prevent this problem the igus® customer can select among 7 jacket materials to adapt the Energy Chain® cables to suit the conditions of the respective environment.

Gusset-filled extruded jacket

Here not only the material is an important factor but also the production process. In the case of the so-called “chain-suitable” cables the jackets are usually produced extruded to the form of a tube and therefore do not provide the stranded structure with the necessary support for constant bending processes. The stranded structure can fall apart.

Therefore, igus® is the first manufacturer of Energy Chain Systems® to offer the so-called “gusset-filled extruded” jacket.

Here, the jacket material is injected between the core stranding powdered with talc and ensures that the stranded structure does not open up and also makes sure that the cores are guided in a channel. The special characteristic of this type of production is that the intermediate spaces, which are created between the cores during the stranding process are completely filled with jacket material by the high extrusion pressure. As a result, the jacket material creates a channel-like guide which allows the cores to carry out a defined longitudinal movement. The jacket also provides a supporting function for the stranding.